The adoption of reusable transport packaging (RTP), including pallets, bins, and containers, is continuing to accelerate in the commercial distribution of goods across the global supply chain. The increase in the adoption of ‘technology-enabled’ reusable transport packaging is further benefiting reusable assets through efficient recovery, return, and redeployment; creating insights into the sustainable performance of supply chains; and improving the reduction of product damage for shipped goods. As adoption has increased, a series of successful use cases have emerged that companies should consider when enabling reusable transport packaging.

The following use cases & case studies are from the global experiences of members of the RPA Technology Working Group (TWG).

Supply Chain + Reusable Transport Packaging

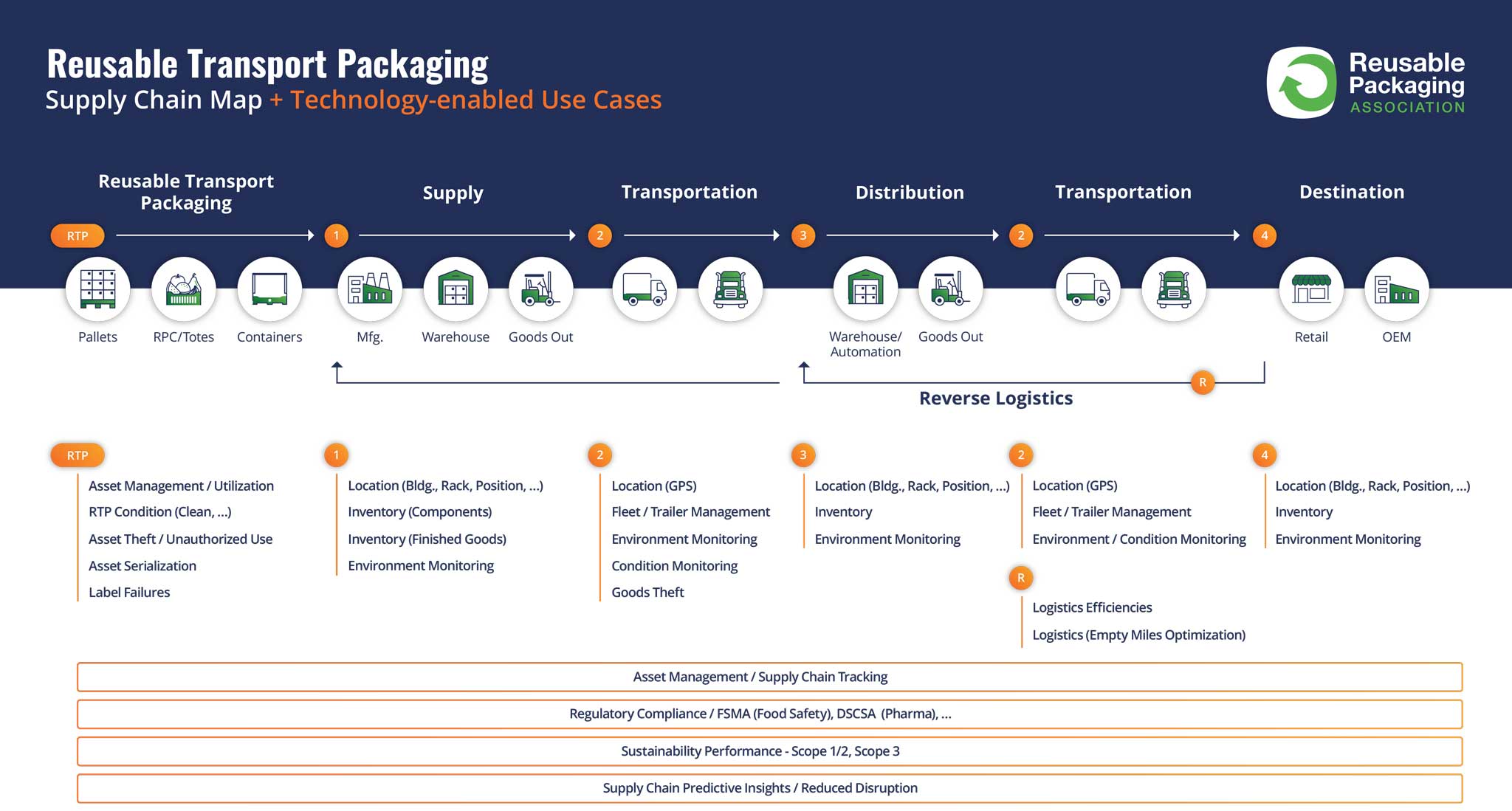

The use of reusable transport packaging is growing each year across many supply chains, which utilize pallets, totes, reusable plastic containers (RPCs), intermediate bulk containers (IBCs), and other reusable assets. Throughout the supply chain, users increasingly need to understand the location, quantity, condition, and compliance of goods moving across their customers’ broader supply chain ecosystems. From this information, users can generate actionable insights, enabling more efficient and sustainable supply chains. Key elements of the supply chain include:

- Reusable Transport Packaging – The reusable assets that move goods to market. Often referred to as secondary or tertiary packaging. (RTP)

- Supply – The manufacturing of goods from raw materials, sub-assemblies, which are moved through transportation & logistics networks to distribution. (1)

- Transportation – The movement of goods, most commonly through trucking and similar resources. (2)

- Distribution – The storage and movement of goods to the final destination, whether to a retailer or OEM. (3)

- Destination – Retailers or OEMs that receive the goods at the end of the supply chain. (4)

- Reverse Logistics – The movement of reusable packaging back through the goods supply chain, where they are serviced and reused in the supply chain. (R)

Supply Chain + Technology-enabled Reusable Use Cases

When starting any technology-enabled reusable packaging project, a company’s leadership and project team must have a holistic understanding of the project’s purpose. Defining the primary ‘Use Case’ with both internal and external customers, as well as other strategic stakeholders across the supply chain, is a crucial first step in any technology-enabled reusable project. After establishing the primary use case, project teams should collaborate with each stakeholder to identify additional secondary use cases as the project scope is finalized.

As technology-enabled reusable transport packaging becomes more common, it is important to focus on proven “use cases” that the project team should consider. The examples below, spanning a supply chain, highlight areas to focus on to discover potential benefits for a company and its broader supply chain ecosystem partners. At the bottom of this page, there are links to RPA member companies that have successfully implemented technology-enabled reusable packaging across various industries with their customers and partners.

”" It is critical to start with the Use Case(s) you are trying to solve, BEFORE selecting a technology-enabling solution. "

Example Technology-enabled Reusable Transport Packaging Use Cases

Reusable Transport Packaging

- Asset Management

- Asset Utilization

- Asset Efficiency

- Asset Theft / Misuse

- Condition Monitoring (Clean, Damaged)

- Labeling Failures

Supply / Manufacturing

- Location

- Building

- Rack / Position

- Inventory

- Raw Materials

- Components

- Finished Goods

- Environmental Monitoring

Transportation

- Location (GPS)

- Fleet / Trailer Management

- Environmental Monitoring

- Condition Monitoring

- Goods Theft / Shrinkage

Distribution

- Location

- Building

- Rack Position

- Inventory

- Environmental Monitoring

OEM / Retailer

- Location

- Building

- Rack / Position

- Inventory

- Finished Goods

- Environmental Monitoring

Ecosystem Use Cases

- Regulatory Compliance (FSMA, DSCSA, …)

- Sustainability Performance (Scope 1/2, Scope 3)

- Predictive Insights / Minimized Disruption

- Supply Chain Resilence Planning

- Supply Chain Insights-driven Optimization

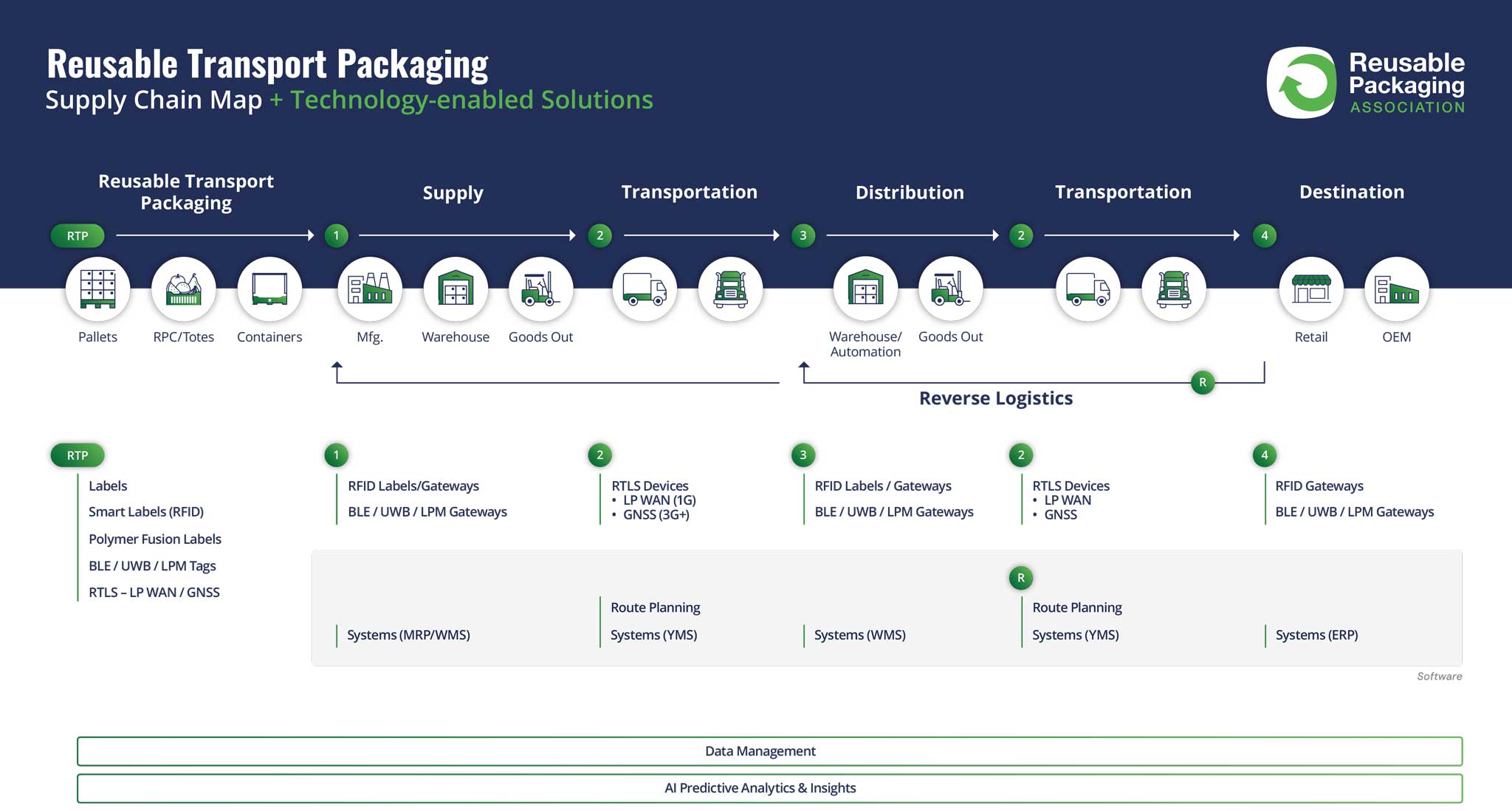

Supply Chain + Reusables Technology-enabling Solutions

A variety of technologies are available to track, identify, monitor, or count goods or assets, as described in the white paper, A Smarter Technology-driven Supply Chain with Reusable Packaging Systems. Technology options include Barcode, RFID, Cellular or LPWAN, Bluetooth Low Energy (BLE), Wi-Fi, and recently introduced technologies such as Self-Organizing Sensor Area Networks, Low Power Mesh, and Ultra-Wideband (UWB) for RTLS (Real-Time Location System).

While there are many variables to consider, the most common is focusing on the ‘value delivered’ relative to the ‘cost of the technology’ to address the identified primary and secondary use cases. Industry experts on the RPA Technology Working Group strongly suggest focusing on the ‘Use Case’ to be solved, versus starting with a technology-enabling solution for reusable packaging.

It is important to note that some companies are applying multi-modality technology-based identification strategies across their network’s pool or fleet of reusable assets when a single technology-enabled solution is not ideal for the entire fleet. This provides a cost-effective solution while still generating data-driven insights by combining technologies and data analytics to derive insights from various data sources. Examples include implementing < 5% of the assets using GPS/GNSS with WAN connectivity, < 20% using BLE or LPM sensors, and 100% using bar codes/RFID data labels.

Below are commonly used technology enablers for reusable transport packaging and related assets, along with the typical use cases they may support.

Use Cases

Inventory / Asset Mgmt.

- Goods In / Out

- Location (Bldg., Room, Rack)

Supply Chain Location

- Asset Management

- Location

Condition Monitoring

- Environmental (Temp., …)

- Condition (Damage, …)

Supply Chain Visibility

- Regulatory Compliance

- Sustainability Scope 1,2,3

- Predictive Insigths

Enabling Technologies

– Hardware

Commonly used technologies

Typically more expensive as you move down the list.

Permanent Labels

- Polymer Fusion

Smart Labels

- RFID Passive / Active

- Infrastructure: RFID Readers

(Hard-wired, Handheld)

BLE (Bluetooth)

- BLE Beacons

- Infrastructure: BLE Readers

(Hard-wired, or smartphone)

UWB

- UWB Asset tag

- Infrastructure: UWB Anchor

(Hard-wired)

LPM (Low Power Mesh)

- LPM Asset tag

- Infrastructure: LPM Reader

(Battery powered)

Cellular

- LP-WAN

- GNSS

- Infrastructure: Not required

BLE (Bluetooth)

- BLE Beacons

- Infrastructure: BLE Readers

(Hard-wired, or smartphone)

UWB

- UWB Asset tag

- Infrastructure: UWB Anchor

(Hard-wired)

LPM (Low Power Mesh)

- LPM Asset tag

- Infrastructure: LPM Reader

(Battery powered)

Cellular

- LP-WAN

- GNSS

- Infrastructure: Not required

BLE (Bluetooth)

- BLE Beacons

- Infrastructure: BLE Readers

(Hard-wired, or smartphone)

UWB

- UWB Asset tag

- Infrastructure: UWB Anchor

(Hard-wired)

LPM (Low Power Mesh)

- LPM Asset tag

- Infrastructure: LPM Reader

(Battery powered)

Cellular

- LP-WAN

- GNSS

- Infrastructure: Not required

Enabling Technologies

– Data Management

– Data Insights

Commonly used as standalone, or ERP, WMS integrations.

Data Management Tools

Predictive Analytics & Insights (AI)

Integrations with

– Warehouse Management Systems (WMS)

– ERP / MRP systems

– Route Planning Systems

Industry Case Studies

Below are technology-enabled reusable packaging case studies completed by RPA Technology Working Group (TWG) member companies. The “Learn more” button links to the industry case study and provides contact information on the RPA member company website.

Use Case: Regulatory Compliance

THE IMPORTANCE OF FOOD TRACEABILITY: IMPACTS ON SAFETY AND BUSINESS

No matter your role in the supply chain, food traceability can play a vital role in securing and improving your business, from ensuring you comply with regulations to helping manage risks (e.g., making recalls faster and more accurate) and connecting with consumers.

Use Case: Asset Management

RFID in-mould label for the GS1 SMART box from Georg Utz GmbH

Reusable packaging is the future. That is why companies from industry and trade agreed some time ago on a new, common container standard for the supply chain between production and central warehouses. In order to be able to use the standardised box in a wide variety of environments and circulation systems, a durable, resistant labelling solution was sought that would combine all auto-ID elements (barcode, 2D code, RFID) on a single label, thus enabling efficient traceability.

Use Case: Permanent Identification

When the Label Becomes the Problem:

How Polyfuze Solved Identification for Reusable Plastics

Polyfuze worked alongside the automotive customer, the packaging design firm, and the RPC manufacturer to integrate polymer-fusion labels directly into the containers, eliminating relabeling events, contamination, and identity loss across the system.

Use Case: Asset Theft

What Happens If You Don’t Track Returnable Plastic Trays?

Companies are under more pressure than ever to increase throughput, reduce waste, and maximize return on investment. One often-overlooked contributor to both cost and inefficiency? Returnable plastic trays.

Use Case: Asset Management

Improving Beverage Delivery Operations with Smart Asset Control

Pallet loss was quietly draining profits for a major beverage distributor until technology changed the game. By pairing the smart-enabled Duo Lift with RFID-equipped pallets and seamless IoT integration, the distributor transformed asset management from guesswork into certainty.

Use Case: Smart Asset Tracking

How RaceTrac streamlines fuel pump repairs with smart tote tracking

With 590+ locations operating 24/7, every minute of pump downtime impacts customer experience. See how real-time visibility into spare parts delivers faster repairs and keeps fuel flowing.

Use Case: Sustainable Supply Chains

How Cummins and Surgere Are Redefining Sustainable Logistics.

With the goal of eliminating 84 million pounds of packaging waste by 2050, Cummins has revolutionized its warehousing and supply chain operations with the help of cutting-edge IoT technology.

Use Case: Asset Management

Micro Fulfillment Centers or Dark Stores: What Real-Time Visibility Reveals

MFCs and dark stores succeed by controlling movement inside compact footprints. Space is limited, workflows move fast, and inaccuracies compound quickly. That’s why real-time asset tracking, powered by GPS, RFID, and IoT sensors, is an essential tool for improving efficiency in modern fulfillment.

Use Case: Environment Monitoring

Temperature-Sensitive Inventory Management

Our AI-powered cold chain monitoring optimized temperature-controlled inventory management for a global CPG company, reducing stockouts by 78% and preventing product degradation through precise environmental control.

Industry Resources

Additional industry resources are available in the RPA Technology Hub for companies considering technology to enable their reusable transport packaging. They include: